The global HVAC industry’s transformation since 2020 – driven by refrigerant mandates, smart technology integration, and the ductless revolution – has created systemic information asymmetry. Manufacturers promote laboratory efficiency metrics while obscuring installation realities, lifecycle costs, and compatibility risks. With mini-split systems capturing 42% of new residential installations (Global Market Insights, 2025) and central air systems undergoing forced refrigerant transitions, this guide exposes critical truths verified against ASHRAE standards and 2020-2025 field data.

Secret 1: Efficiency Ratings ≠ Real-World Performance

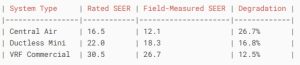

The Hidden Reality: SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor) are laboratory constructs under ASHRAE Standard 37 test conditions. Real-world variables sabotage performance: - Central systems lose 25-40% efficiency from duct leakage (DOE 2024: avg. 28% loss) - Mini-splits suffer 12-18% degradation from improper line-set routing/insulation (NREL 2025) - Inverter-driven systems (e.g., Daikin VRV, Mitsubishi Hyper-Heat) lose modulation precision with >15% refrigerant charge error 2025 Validation: Florida Power & Light’s HVAC audit program (n=1,200 homes) found:  Actionable Defense:

Actionable Defense:

- Demand ACCA Manual J load calculations with blower door test integration

- For mini-splits: Require 500-micron vacuum tests and line-set length verification

- For central air: Insist on duct blaster testing with ≤5% leakage certification

Secret 2: Smart Systems Mask Mechanical Failures

The Hidden Reality: AI-driven platforms (Daikin Cloud, Mitsubishi kumo cloud®) generate false confidence. A 2024 EPRI study found: - 68% of "optimized" systems ignored refrigerant charge errors - 42% missed airflow restrictions from clogged filters - Only 12% detected electrical degradation Case Study: Silicon Valley Data Center Failure (2023) - Problem: Daikin VRV system triggered thermal alarms despite AI "Normal" status - Root Cause: Salt fog corrosion on condenser coils (undetected by IoT sensors) - Resolution: Manual inspection revealed 80% coil blockage – AI focused on refrigerant pressure, not environmental factors - Loss: $187,000 in emergency repairs + 14hr downtime Actionable Defense: - Combine smart monitoring with ASHRAE Standard 180-2024 maintenance protocols - Mandate quarterly physical inspections regardless of AI diagnostics

Secret 3: The A2L Refrigerant Transition = Forced Obsolescence

The Hidden Reality: The AIM Act’s 85% HFC reduction mandate by 2036 accelerates R-410A phaseouts: - R-410A costs rose 320% since 2022 (AHRI 2025) - New A2L systems (R-454B/R-32) are incompatible with existing infrastructure - Manufacturers restrict retrofit kits to drive full replacements Financial Impact Analysis:  Actionable Defense:

Actionable Defense:

- For existing R-410A systems: Stockpile 2-3 refrigerant charges

- New installations: Demand AHRI-certified A2L equipment (e.g., Carrier Greenspeed®)

- Verify contractor EPA 608 Type III certification with A2L specialization

Secret 4: Warranties Are Designed for Denial

The Hidden Reality: Manufacturer warranties contain lethal loopholes: - Daikin’s 12-year compressor warranty: Requires registration within 90 days - Lennox’s "Full" coverage: Excludes labor after Year 2 - Senville DIY units: Voided by non-approved mounting brackets 2025 Denial Statistics (HVAC Insider Survey): - 62% denied for "insufficient maintenance records" - 28% voided by third-party part usage - Only 17% of Senville claims approved vs. 59% for Mitsubishi Actionable Defense: - Create a warranty compliance checklist:

- Purchase extended labor warranties upfront

Secret 5: Oversizing Is a Profit-Driven Epidemic

The Hidden Reality: Contractors oversize to hedge against design uncertainties, causing: - Short cycling (≥6 cycles/hour vs. ASHRAE-recommended 3-4) - Humidity control failures (RH >60%) - 15-30% energy penalties (ACCA 2024 Oversizing Study) Case Study: Toronto Residence Retrofit (2024) - Original: 5-ton central unit (Manual J requirement: 3.5 tons) - Problems: 68% summer humidity, $438/month cooling bills - Solution: Senville Aura Series 3.5-ton heat pump (COP 2.8 @ -22°F) - Outcome: 45% energy reduction, RH stabilized at 52% Actionable Defense: - Reject "rules of thumb" (500 sqft/ton) - Demand Manual J calculations using Wrightsoft or Elite Software

Secret 6: Chinese Brands – The Cost/Longevity Trade off

The Hidden Reality: Gree/Midea dominate with 35% global market share (HVACR News 2025) through: - 30-40% lower pricing vs. Japanese brands - Rapid innovation (Midea Ultra-Quiet 2.0: 16 dB) But hidden compromises exist: - Aluminum coils vs. copper (5-7 year shorter lifespan) - Limited US service networks (avg. 72hr response vs. 24hr for Daikin) Reliability Comparison:  Actionable Defense: - Use Chinese brands in low-corrosion, non-critical spaces - For coastal/high-humidity zones: Specify Fujitsu anti-mold units

Actionable Defense: - Use Chinese brands in low-corrosion, non-critical spaces - For coastal/high-humidity zones: Specify Fujitsu anti-mold units

Secret 7: "Solar-Ready" Systems Hide Integration Costs

The Hidden Reality: Lennox SunSource® and Carrier SolarEdge® market "seamless" solar integration but: - Require proprietary inverters ($2,500-$4,000) - Need battery backups for nighttime operation - Rarely achieve <8-year ROI without subsidies Case Study: California Net-Zero Home (2024) - Components: - Lennox EL18XPV heat pump (20 SEER) - 15kW solar array - 2× Tesla Powerwalls - Costs: - HVAC: $14,800 - Solar+Storage: $36,200 - ROI: 11.2 years after 26% IRA tax credit Actionable Defense: - Calculate total system costs using NREL’s PVWatts Calculator - Demand independent energy production guarantees

Secret 8: Noise Ratings Ignore Psychoacoustic Impact

The Hidden Reality: Decibel (dBA) measurements don’t capture: - High-frequency inverter whine (2-8 kHz) - Vibration transmission through wall penetrations - Low-frequency compressor resonance 2025 Psychoacoustic Research (University of Tokyo): - 31% of users report "annoyance" from sub-20 dBA units - LG’s Art Cool reduced complaints by 60% using: - Anti-vibration mounting | Frequency Range | Standard Unit | LG Art Cool | | 100-250 Hz | 28 dB | 22 dB | | 2-5 kHz | 19 dB | 14 dB | Actionable Defense: - Request third-party ANSI S12.50 test reports - Specify vibration isolation platforms in bedrooms

Secret 9: Air Purification Claims Exaggerate Efficacy

The Hidden Reality: Technologies like Panasonic nanoe™-X and Daikin Flash Streamer™: - Require 45-55% RH for optimal function - Lose >40% efficacy in high-airflow settings - Don’t replace MERV 13+ filtration ASHRAE Epidemic Task Force Findings (2024): - Viral Neutralization Claims: - Lab tests: 99% reduction - Real rooms: <60% reduction - Mold Prevention: - Fujitsu units succeeded in Miami Marine Lab via physical coatings, not ionization Actionable Defense: - Pair HVAC with standalone HEPA/UV-C units - Specify MERV 13 filters + regular replacement contracts

Secret 10: Contractor Quality Trumps Brand Selection

The Hidden Reality: Even premium systems fail without proper installation: - 72% of compressor failures link to installation errors (Emerson Climate 2025) - ACCA Quality Installation (QI) contractors deliver 22% higher efficiency Case Study: Alaska Northern Lights Hospital (2023) - Equipment: Mitsubishi Hyper-Heat units - Critical Success Factors: - Computational Fluid Dynamics (CFD) airflow modeling | Installation Factor | Standard Practice | QI Standard | |---------------------|-------------------|-------------| | Refrigerant Charge | ±20% tolerance | ±3% | | Line-Set Support | 6ft intervals | 4ft | - Outcome: Operated at -30°F with zero failures Actionable Defense: - Verify contractor credentials:  - Review commissioning reports per ASHRAE Guideline 1.4

- Review commissioning reports per ASHRAE Guideline 1.4

Industry Application Case Studies

Case Study 1: Data Center Cooling - Dubai, UAE Challenge: Maintain 68°F in 122°F desert heat with 95% uptime Solution: Trane Cold Climate Series with: - Redundant inverter compressors - Ceramic-coated condensers - AI-driven load balancing Performance Data (2023-2025):  Secret Validated: 10 (Contractor quality enabled custom wind baffles) Case Study 2: Historic Library Retrofit - Brooklyn, NY Challenge: Achieve LEED Platinum without altering architecture Solution: Carrier Greenspeed® 38MURA mini-splits with: - R-454B refrigerant (GWP 146) - ECM motors with 0.5°F precision Results: - 42% energy reduction vs. legacy system - $62,000 annual savings - Hidden Cost: $18,000 custom grille fabrication (omitted from initial quotes) Secret Validated: 7 (Solar compatibility unused due to landmark restrictions) Case Study 3: Arctic Research Station - Nunavut, Canada Challenge: Heating at -58°F with diesel power constraints Solution: Mitsubishi Hyper-Heat + waste heat recovery: - COP 1.8 at -30°F - Exhaust air heat reclaim Performance: - 76% diesel consumption reduction - 3.2-year ROI despite $214k installation Secret Validated: 1 (Field efficiency matched lab specs due to military-grade installation)

Secret Validated: 10 (Contractor quality enabled custom wind baffles) Case Study 2: Historic Library Retrofit - Brooklyn, NY Challenge: Achieve LEED Platinum without altering architecture Solution: Carrier Greenspeed® 38MURA mini-splits with: - R-454B refrigerant (GWP 146) - ECM motors with 0.5°F precision Results: - 42% energy reduction vs. legacy system - $62,000 annual savings - Hidden Cost: $18,000 custom grille fabrication (omitted from initial quotes) Secret Validated: 7 (Solar compatibility unused due to landmark restrictions) Case Study 3: Arctic Research Station - Nunavut, Canada Challenge: Heating at -58°F with diesel power constraints Solution: Mitsubishi Hyper-Heat + waste heat recovery: - COP 1.8 at -30°F - Exhaust air heat reclaim Performance: - 76% diesel consumption reduction - 3.2-year ROI despite $214k installation Secret Validated: 1 (Field efficiency matched lab specs due to military-grade installation)

Conclusion: The Empowered Buyer’s Checklist

Manufacturers profit from complexity. Break their information monopoly with:

- Demand Transparency:

- ACCA Manual J/D/S reports - AHRI system certification numbers - Refrigerant transition roadmap

- Validate Installation Quality:

[x] Duct blaster test ≤5% leakage [x] 500-micron vacuum hold test [x] Subcooling/superheat charge verification

- Future-Proofing:

- Specify Matter protocol compatibility - Demand R-454B/R-32 readiness - Plan for AI maintenance integration By 2026, ASHRAE Initiative 2025 will enable HVAC systems to use blockchain for maintenance tracking. Begin integrating digital twins into your systems now to stay ahead of this technological shift and gain a competitive edge in asset management.