On a hot afternoon, the central air-conditioning system in a commercial complex suddenly stopped cooling, and the welcome hall began to swelter. After inspection by the technical team, it was found that the problem was caused by the “burning” of the compressor of the outdoor unit. In the face of this diagnostic report, the developer and the property party are caught in the choice: whether to replace only the core components of the compressor, or simply replace the entire outdoor unit or the entire air conditioning system together? This seemingly simple option actually has multiple dimensions behind the device life, system matching, cost benefit, energy efficiency standards, future regulations and risk control. Next, we’ll look at several aspects of how to make this choice.

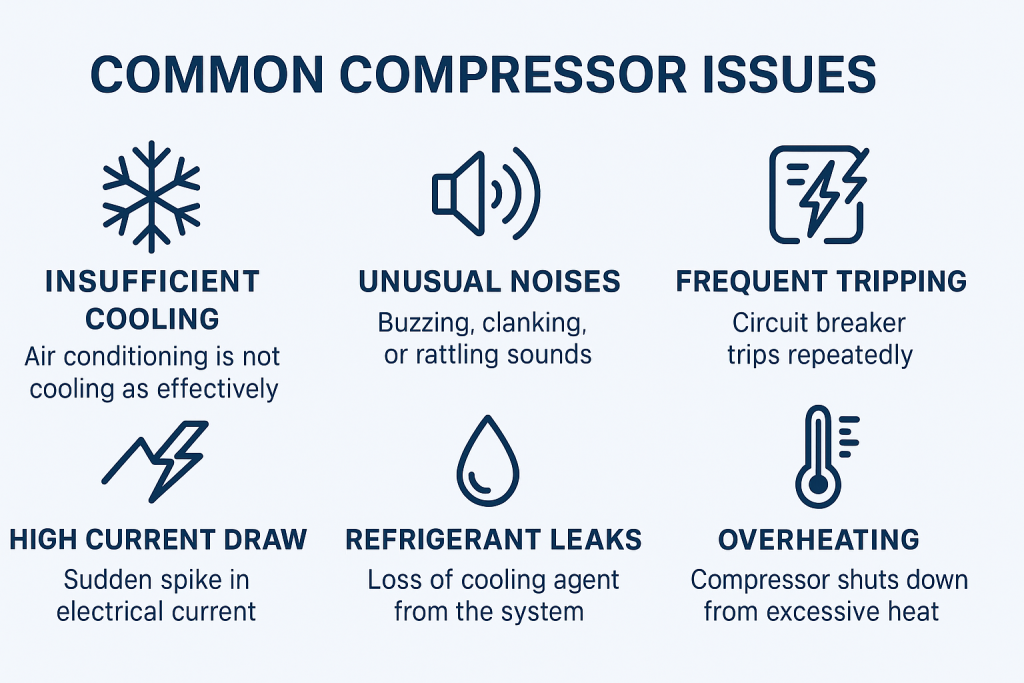

The Compressor’s Role and Signs of Failure

Compressors can be regarded as the “heart” of an air conditioning system – they are responsible for compressing low-pressure refrigerants into high-pressure gases, driving the cooling cycle to convert heat. If the compressor is abnormal or completely fails, the entire system cannot be cooled properly.

Since compressors are usually designed to be sealed, internal component internal damage such as bearing wear, cylinder block scratch, valve disc failure is almost irreparable in the field and can only be dealt with by replacing a new compressor module. This point is clearly emphasized in many HVAC professional sources.

Before judging whether to replace the compressor, the first thing to do is to identify typical compressor failure signals: first, the cooling capacity drops sharply or disappears completely, even if the cooling load is unchanged. Secondly, the system may be difficult to start, compressor noise, friction, knock, or vibration. Electrical abnormalities such as circuit protection trips, fuse fuses, abnormal power increases, and current exceeds the standard may also be a warning of abnormal compressor load.

In addition, refrigerant leakage, abnormal oil level, insufficient lubrication, pipeline blockage may cause or exacerbate compressor failure, in this case, simply changing the compressor to solve the surface problem may not be enough.

As a rule of thumb, many maintenance engineers in community forums or industry reviews tend to say, “If the system is ten years old, the compressor is broken, don’t fix it, just replace it” – for example, r/hvacadvice has a technician who says that after years of service, he usually advises clients to replace the whole machine instead of the compressor road.

Expected Compressor Lifespan and System Aging

Situations suitable for replacing the compressor

In the following several situations, replacing only the compressor might be a reasonable choice:

- The entire system is relatively young (usually less than 8 to 10 years old), and other components of the system are in good condition.

- The compressor is still within the warranty period or still covered by the warranty policy.

- The maintenance quotation is reasonable and significantly lower than the cost of replacing the entire machine.

- The owner hopes to restore the system operation in the short term first, and then consider it based on the overall performance in the future.

- The system uses a relatively new standard, the refrigerant still complies with the regulations, and the risk of future upgrades is small.

In these scenarios, replacing the compressor can restore system functionality at a relatively low cost while avoiding large-scale construction disruptions.

There is a tendency to replace the entire machine

However, in many cases, replacing the entire machine is a wiser choice for the following reasons:

- The system is already 10 to 15 years old or even older, and other components may malfunction at any time.

- The total cost of replacing the compressor and the associated system cleaning, pipeline cleaning, oil replacement, control component replacement, commissioning, etc. is close to the cost of resetting the entire machine.

- The original system used refrigerants that were phased out or restricted (such as R-22); After the compressor is replaced, there may still be issues such as refrigerant compatibility, regulatory compliance, or parts replacement.

- The owner has long-term energy-saving, efficiency improvement, environmental compliance or future expansion needs and wants to upgrade to a high-efficiency model through this.

- There are already cost-effective alternative solutions for new machines in the market. The replacement of the entire machine brings about improved efficiency and simplified maintenance.

HVAC.com clearly pointed out in its article that when the system is 10 to 15 years old or longer, the maintenance cost is high, and the system efficiency decreases, replacing the entire machine is often a more stable long-term solution.

Another information points out that if the compressor failure becomes the cause of the replacement of the whole machine, then the replacement of the whole machine is usually more economically reasonable.

Compressor Replacement vs. Full System Replacement: Pros and Cons

When Replacing the Compressor Makes Sense

There are scenarios where replacing only the compressor can be a practical solution:

- The system is relatively new (typically under 8–10 years old) and in otherwise good condition.

- The compressor is still under warranty or eligible for extended coverage.

- Repair costs are significantly lower than replacement costs.

- The priority is quick restoration of cooling, with long-term planning deferred.

- The system uses a current refrigerant that complies with existing regulations.

In these cases, compressor replacement can restore system function at a lower short-term cost, with minimal disruption.

When Full Replacement Is the Better Option

On the other hand, there are many situations where full system replacement is the smarter long-term choice:

- The system is already 10–15 years old, and multiple components are approaching end-of-life.

- Total compressor replacement costs—including cleaning, flushing, oil changes, parts, and labor—are close to the cost of a new system.

- The system uses outdated or banned refrigerants such as R-22, which pose compatibility and regulatory issues even after compressor replacement.

- There is a desire to upgrade to higher-efficiency models for energy savings and regulatory compliance.

- Market conditions make new systems a cost-effective option, often with improved warranties and lower long-term operating expenses.

HVAC experts, including those at HVAC.com, emphasize that when a system is older, less efficient, or increasingly unreliable, full system replacement usually provides a more stable, long-term solution.

The 50% Rule of Thumb

In the industry, a common empirical judgment method is the “50% rule” : if the cost of replacing the compressor (including disassembly and assembly, system cleaning, parts updating, labor, debugging, etc.) exceeds 50% of the replacement cost of the new whole machine, then the whole machine is preferred to be replaced. This rule provides a simple but practical reference point for judgment.

In addition, when replacing the compressor, the business side should require detailed parts list, quantity details, labor hours, system commissioning costs, etc., so as to clearly compare with the quotation of the whole machine. And take into account the “estimated future maintenance cost” : even if the current cost is low, the remaining life of the system, reliability and the potential for failure after the compressor is replaced need to be evaluated together.

A Practical Decision Framework

Here’s a practical framework for developers, property managers, and homeowners to follow:

- Obtain multiple professional assessments. Always consult at least two licensed HVAC contractors for diagnostic reports and cost estimates.

- Evaluate system age and condition. Consider total years of service, repair history, and the health of other major components.

- Compare costs. Weigh compressor replacement costs against full system replacement, applying the 50% Rule as a benchmark.

- Consider refrigerant and regulations. Outdated refrigerants like R-22 pose future compliance and availability risks.

- Review warranty coverage. Full system replacement often comes with comprehensive new warranties, while compressor-only replacements may be more limited.

- Factor in future maintenance. Look beyond the immediate repair and budget for the next 5–10 years of service and efficiency.

- Make a balanced decision. Incorporate technical, financial, and regulatory perspectives to reach the most rational choice.

Case Example: Repair vs. Replacement

Consider an office building with a 12-year-old central AC system. The compressor has failed, and contractors provide the following quotes:

- Compressor replacement: $8,000, including compressor, flushing, oil changes, filters, and labor.

- Full system replacement: $15,000, including new outdoor and indoor units, installation, and commissioning.

By the 50% Rule, compressor replacement costs already exceed half the cost of full replacement. Factoring in system age, potential for further breakdowns, and efficiency gains from a new system, full replacement emerges as the more cost-effective long-term choice.

Key Risks and Considerations

Whichever option you choose, keep these risks in mind:

Beware of “quick fix” promises. Replacing the compressor without addressing system health may lead to mismatches and inefficiency.

Efficiency loss with mismatched parts. A new compressor paired with aging coils and fans may not deliver its rated performance.

Refrigerant compliance issues. New compressors may not be compatible with outdated refrigerants, creating regulatory or safety concerns.

Hidden costs. System flushing, line cleaning, and downtime may inflate repair costs beyond the initial quote.

Warranty limitations. Compressor replacements often carry shorter or more restricted warranties than full system replacements.

Project downtime. While full replacement involves more installation work, it usually reduces the risk of repeat failures and disruptions.

Conclusion: No One-Size-Fits-All Answer

Repair the compressor or replace the whole machine, there is no standard answer that applies to all projects. The key is to use data, costs, longevity, system health, and future goals to determine. If the system life can be expected in the future, the overall condition of the equipment is good, and the maintenance cost is reasonable, it may be more economical to choose to replace the compressor.

However, if the system is aging, maintenance costs approach replacement, and you want to achieve energy efficiency upgrades or reduce subsequent risk, then replacement may be a more stable long-term solution.

For developers and homeowners, it is really important to consider the whole picture at the moment of getting the offer: parts cost, labor, debugging, system matching, operational efficiency, future repair risk and warranty terms. Only through comprehensive comparison and reasonable judgment can the most appropriate choice between technology and business be made.