Selecting the reliable HVAC supplier is often the difference between the success and failure of the entire project. A trusted partner not only provides high-quality equipment, but also ensures smooth communication, timely delivery, and reliable support throughout the project lifecycle.

But the HVAC supply chain system can be complex or even prohibitive for first-time buyers or project developers. How to accurately judge whether a supplier is reliable? What should be done before the contact? How to effectively promote the cooperation process?

This step-by-step guide will help you identify, scientifically evaluate, and ultimately establish solid relationships with HVAC suppliers that are the right fit for your project.

First Impression: How to Determine if a supplier is reliable

Company Background

Check its establishment year, business scale and project history. Suppliers that own factories and can showcase global project cases are usually more trustworthy.

Check whether it has relevant certifications, such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and product certifications such as AHRI, CE or UL.

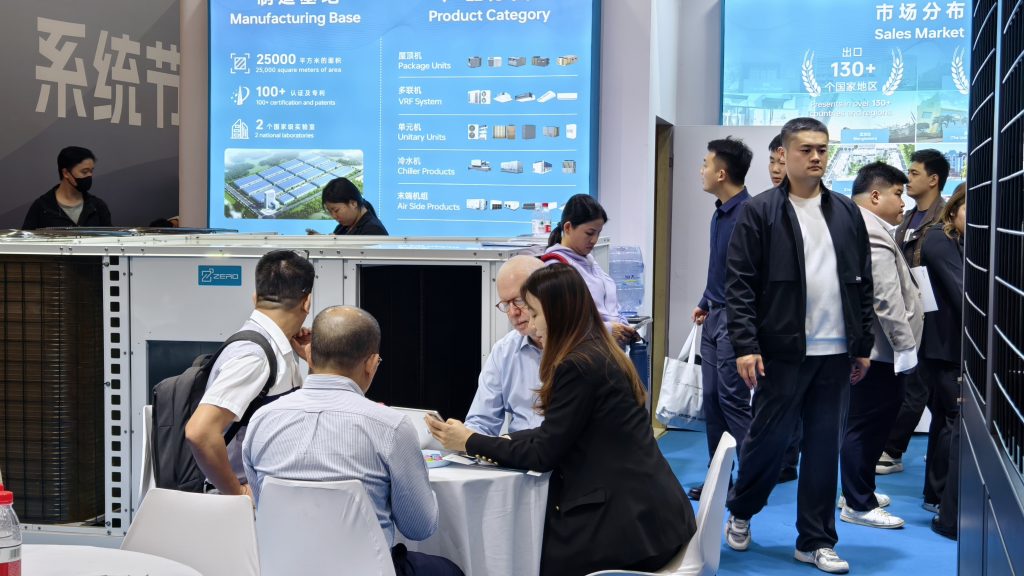

Market presence

Do they maintain professional websites, publish project case studies, or actively participate in international exhibitions?

Continuous industry exposure means long-term stability and credibility.

Product and solution capabilities

A reliable supplier should be able to offer a complete HVAC product line – from residential split units, VRF systems, to chillers, rooftop units and modular solutions. This can prevent you from making scattered purchases from multiple suppliers.

More importantly, outstanding suppliers not only sell products but also offer complete solutions, covering system design, product selection, configuration, installation guidance and after-sales service. This can reduce risks and ensure the smooth implementation of the project.

Customer feedback

Ask the other party to provide customer recommendations or case evaluations.

Warning signs include: ambiguous responses, refusal to share cases, and lack of real project experience.

Professional tip: The best suppliers do not merely sell products, they offer comprehensive solutions to help you complete your projects faster, more efficiently, and with lower risks.

What to Prepare Before Engaging with Suppliers

Suppliers will evaluate you just as you evaluate them. To move discussions forward smoothly, prepare these materials:

Project Requirements Sheet

Cooling/heating capacity needed (in tons or kW).

Application scenario (residential, commercial, industrial, or special projects).

Preferred refrigerants (R32, R454B, R410A, etc.).

Voltage/frequency standards (e.g., 220V/60Hz, 380V/50Hz).

Budget Range & Timeline

Even an approximate budget helps suppliers recommend appropriate models.

Clarify your project timeline (when equipment is required on-site).

Compliance & Standards

If your project requires local certifications (e.g., CE in Europe, AHRI in the U.S.), prepare this info so the supplier can confirm compliance.

Questions List (must-have topics to cover):

What is your standard lead time from order to delivery?

Do you provide installation and after-sales support?

How flexible are you with customization (branding, technical adjustments)?

Can you share recent project references similar to mine?

What warranty terms are included?

During Negotiation: How to “Read” the Supplier

While discussing with the supplier, pay attention to their communication style and transparency:

Responsiveness: Do they reply promptly and with clear answers?

Technical Depth: Can they explain product specs in detail and adapt them to your project scenario?

Flexibility: Are they willing to adjust proposals to fit your budget or timeline?

Documentation Quality: Serious suppliers will provide professional brochures, data sheets, and proposals, not just informal price quotes.

Green Flag: A reliable supplier proactively asks about your project details (not just price). This shows they want to provide a solution, not just sell a product.

Moving On: Building a Smooth Cooperation

Once you confirm the supplier is reliable, here’s how to keep the process moving efficiently:

Start with a Pilot Order

For large-scale projects, test their delivery and quality with a smaller order before committing to full capacity.

Clarify All Terms in Writing

Confirm product specs, payment terms, delivery schedule, and warranty in the contract.

Avoid vague verbal agreements.

Set Communication Channels

Agree on a main point of contact (sales engineer, project manager).

Use professional tools (email, project management software) rather than relying solely on messaging apps.

Plan for After-Sales

Ensure you know who to contact for spare parts, troubleshooting, or warranty issues.

A dependable supplier will have structured after-sales procedures.

Conclusion: A Supplier is a Long-Term Partner, Not Just a Vendor

Finding the right HVAC supplier is about more than comparing prices. It’s about securing a partner who shares your standards for quality, reliability, and service. With proper due diligence, clear requirements, and structured communication, you can confidently choose a supplier that supports your project success and business growth.

Remember: The best supplier isn’t just the one that sells equipment—it’s the one that provides a full product range and complete solutions, helping you deliver comfort, efficiency, and peace of mind to your clients.