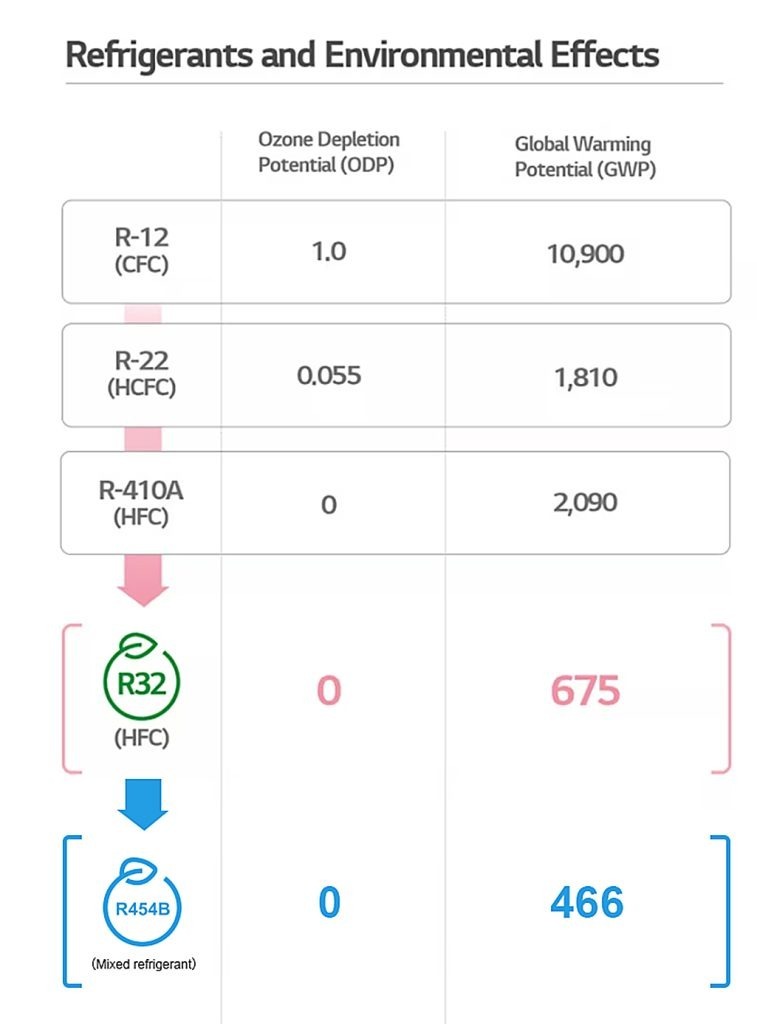

In air-conditioning applications, more and more manufacturers are turning to low-GWP and low-cost alternatives to R410A. In view of the Kigali Amendment to the Montreal Protocol and other restrictive policies such as the European F-Gas regulation. Many air conditioners have begun to phase down their use of HFC refrigerants such as R410A. The aim is to reduce direct carbon emissions and slow down global warming, and there are a number of suitable alternatives to refrigerants such as R410A. This article examines the uses, advantages and disadvantages of R32 and R454B as alternatives to conventional refrigerants.

What is refrigerant?

Refrigerant is the medium that enables the refrigeration system to work, and it can take away heat through the cycle of liquefaction and vaporization, so as to achieve the effect of cooling or heating.

Specifically, refrigerant is a special class of working fluid that can be continuously vaporized and liquefied. It undergoes phase changes in different components of the refrigeration cycle to accomplish the transfer of temperature and heat.

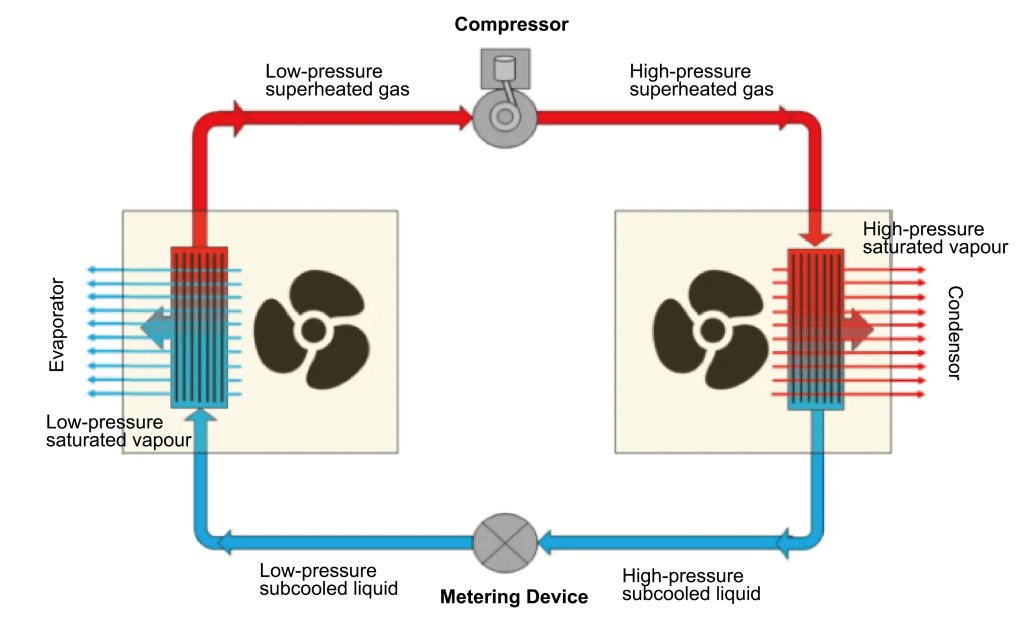

How refrigerants work?

Principle of operation of refrigerants. Based on the property that a refrigerant absorbs or releases a large amount of heat during a phase change.

A typical refrigeration cycle consists of the following processes.

- Compression

The compressor is used to compress the refrigerant into a high-temperature, high-pressure gas. In this process, the compressor provides compression work for the refrigerant, which increases its temperature significantly.

- Compression

- Condensation

The high temperature and high pressure gas after compression releases heat in the condenser and condenses into a liquid state, i.e. the phase change from gas to liquid.

- Condensation

- Expansion

Liquid refrigerant through the expansion valve when the pressure and temperature drop rapidly, the appearance of gas-liquid two-phase state of the refrigerant.

- Expansion

- Evaporation

Low-pressure two-phase refrigerant enters the evaporator, where it absorbs the surrounding heat and vaporizes, completing the phase change from liquid to gas.

- Evaporation

- Circulation

The vaporized refrigerant gas re-enters the compressor and starts a new cycle.

- Circulation

In this phase change cycle, the refrigerant takes away the heat in the condenser and releases this heat at the evaporator, completing the transfer of heat to achieve the effect of refrigeration. Therefore, in the process of air conditioning operation, refrigerant is an essential part.

Introduction of common refrigerants

- HCFC refrigerants

These refrigerants: R22, R123, R124,etc. Containing chlorine and fluorine, destroy the ozone layer and are now being phased out.

- HCFC refrigerants

- HFC refrigerants

For example, R410A, R32, R134a, etc. These are non-chlorine fluorocarbon refrigerants. These non-chlorine fluorocarbon refrigerants do not deplete the ozone layer, but cause the greenhouse effect. Now being gradually replaced by new refrigerants with low GWP. Although R32 is also an HFC refrigerant, it has a low GWP, is more environmentally friendly, and is widely used worldwide.

- HFC refrigerants

- HFO refrigerants

For example, R290, R1234ze and so on. These new environmentally friendly refrigerants have lower global warming potential (GWP) and are considered as environmentally friendly alternatives to HCFC and HFC.

- HFO refrigerants

- Mixed refrigerant

Will be two or more pure refrigerants mixed in proportion to achieve a comprehensive performance balance. For example, R410A (R32 and R125 approximate 50/50 blend) and R454B (R32, R1234yf blend).

- Mixed refrigerant

At present, the widely used common refrigerants are mainly HCFC-based R22 and HFC-based R410A, but in the future they will be gradually replaced by new environmentally friendly refrigerants with low GWP, such as R32 and R454B.

R32 Refrigerant

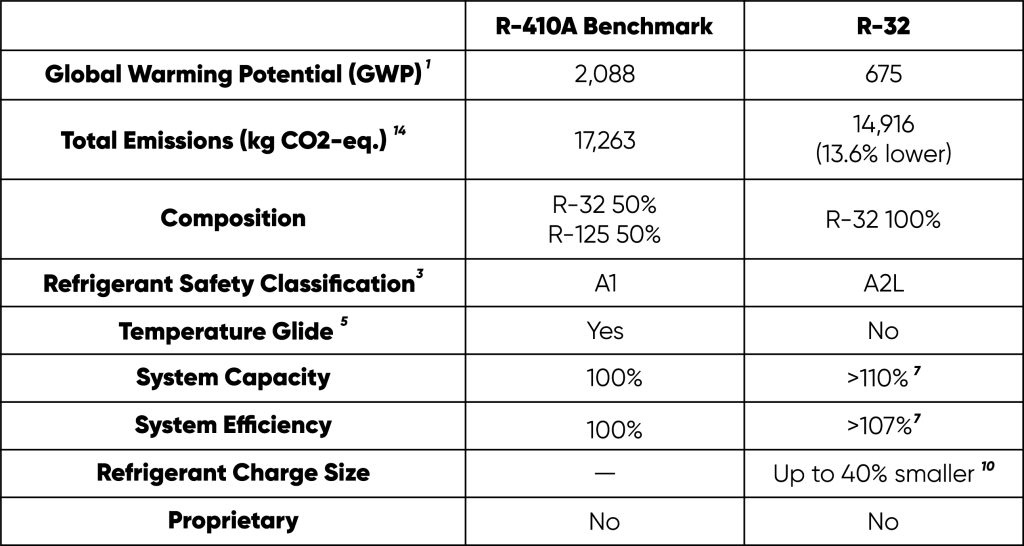

As a pure, single component refrigerant, R-32 can be added or recharged in the field in both liquid and gas phases, without changes in composition. It is easy to clean, reuse on-site, and easy to reclaim off-site with a simple cleaning process.

R-32 has been adopted as a refrigerant in over 160 million air conditioning units globally by more than 40 original equipment manufacturers. It has been utilized safely and effectively in these systems across a wide range of countries and climates. With over 100 countries now moving towards using R-32 as the replacement for R-410A, it has essentially become the de facto standard refrigerant to transition away from R-410A worldwide. Based on the broad industry adoption and successful track record of reliable performance, R-32 has proven itself to be a viable and preferred environmental-friendly refrigerant option to replace R-410A.

R32 refrigerant, as a new low global warming potential (GWP) alternative refrigerant, has the following main advantages and disadvantages.

Advantages:

- Low GWP. R32 has one-third of the GWP of R410A and has a minimal environmental impact.

- Large refrigeration capacity, energy efficiency than the existing refrigerant R410A improved.

- Good thermal conductivity, good system cooling effect.

- Wide operating temperature range, stable characteristics.

- Good compatibility with common lubricating oil such as mineral oil.

Disadvantages:

- The working pressure is about 45% higher than that of R410A, which requires higher system closure.

- The flammability is slightly greater than R410A, which belongs to the A2L class of slightly combustible refrigerant.

- The temperature slip is large, and the evaporation capacity decreases at low temperatures.

- The compressor is easily damaged after the liquid refrigerant overheats.

- Strong corrosion to some materials and seals.

Overall, R32 has outstanding environmental performance, excellent performance, is a promising low GWP refrigerant, but in the application of the need to pay attention to the safety and adaptability of the device.

R454B Refrigerant

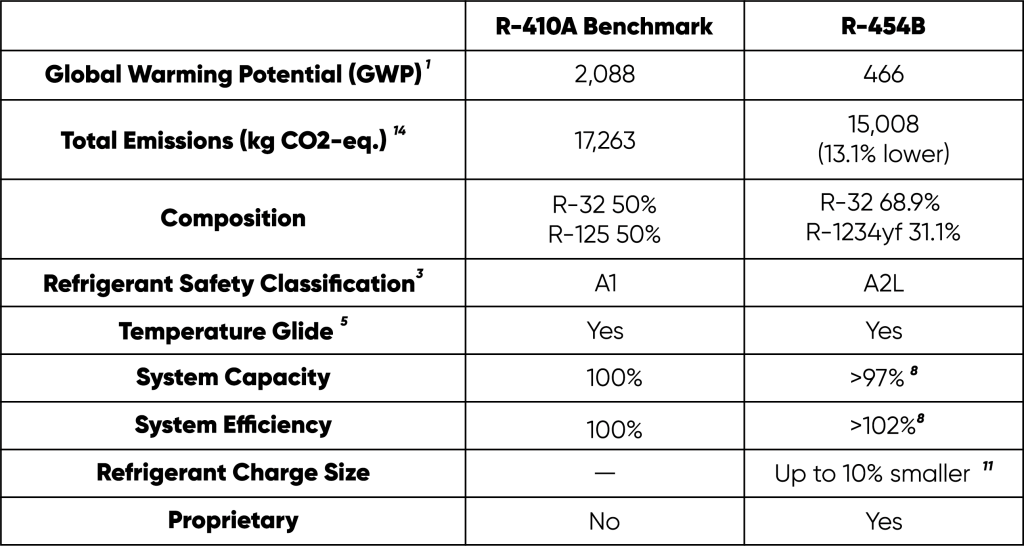

R-454B is a blend and it must be charged like R-410A. The components of R-454B leak at different rates, while R-32 is a single component refrigerant and can be added in the field without concern of composition change.

Unlike R-32, the R-454B refrigerant has seen much more restricted adoption worldwide. There have only been a few limited pilot test cases of residential air conditioning systems using R-454B, as products containing this refrigerant are not yet approved and commercialized in the United States market. Compared to the widespread global use of R-32 in over 160 million units, R-454B usage has remained very minimal overall. The lacks of regulatory approval and commercial availability have severely limited R-454B implementation in real-world AC systems, especially for residential applications.

At present, R-454B lacks the globally established market presence and extensive real-world track record that R-32 possesses. Significant further development is needed for R-454B refrigerant to demonstrate reliable performance and gain acceptance as a potential replacement candidate for R-410A systems.

As a new type of mixed refrigerant, R454B has the following advantages and disadvantages:

Advantages:

- Low GWP value, about one-fifth of R410A, more environmentally friendly.

- The cooling performance is equivalent to or even better than R410A, with large cooling capacity and high efficiency.

- Moderate working pressure, close to R410A, less impact on existing equipment.

- Good flammable performance and high safety.

- Good compatibility with common materials and lubricating oil.

Disadvantages:

- Higher slippage, significant drop in cooling capacity at low temperatures.

- Higher requirements for compressor displacement and efficiency.

- The effect of long pipeline system may be slightly worse than R410A.

- Leak detection is more difficult, need special leak detection equipment.

- the current production and application scale is small, not enough experience.

On the whole, R454B is a kind of transitional refrigerant blend with balanced efficiency and environmental protection, which is expected to replace R410A and R407C in specific applications, but more experience data need to be accumulated.

Application Prospects for R32 and R454B

Under the background of global warming, low GWP refrigerants are regarded as the key technology choice to realize the low-carbon transformation of the industry. Many developed countries and regions have formulated mandatory policies and regulations for the use of low GWP refrigerants in air conditioners and heat pumps, and R32 and R454B are fully in line with this industrial development direction.

The European Union has implemented the policy of banning the use of high GWP refrigerants in new equipment from 2022. North America, Japan and other regions have also introduced similar policies and regulations, clear market share requirements for low GWP refrigerants in the next few years. This has created policy drivers for R32 and R454B applications.

Including Panasonic, Daikin, Carrier, Colin and other well-known global air conditioning manufacturers have announced a different scale of low GWP refrigerant transition program, which R32 and R454B as the focus of alternative refrigerants. It is expected that by 2026, at least 30% of the world’s newly produced air conditioners will use R32 or R454B.

Developing countries due to strong demand for air conditioning and other home appliances, but also gradually realize the low-carbon, efficient refrigerant upgrade, China and India have introduced industrial policies to promote the rapid popularization of R32, R454B.

The rapid development of renewable energy will also create a larger market for low GWP refrigerants for green refrigeration solutions.

Therefore, R32 and R454B have broad global application prospects, and are expected to become the most widely used low-GWP environmental refrigerants in the HVAC field in the next decade.

Some of the images are from the Internet, DM us for credits or removal issues.